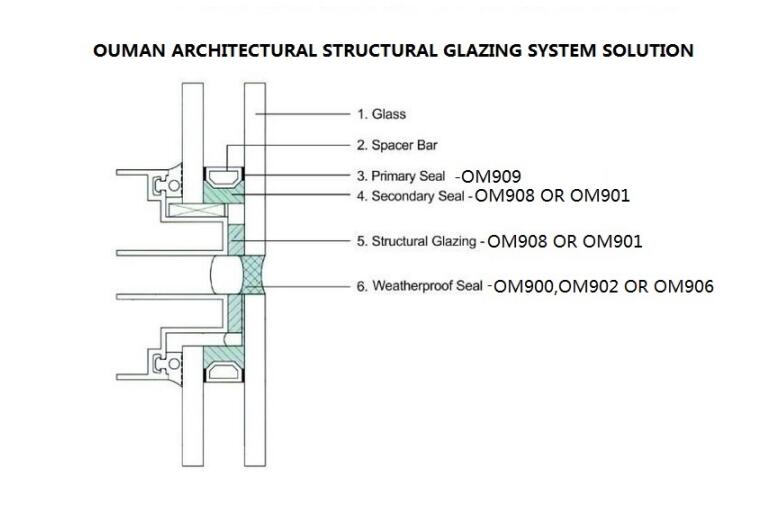

◎Specification.

This specification specifies the preliminary preparation, basic requirements, process procedures, and quality inspection methods for the construction of building glass curtain wall structural components bonded with silicone structural sealant. Suitable for guiding the construction and application of silicone structural sealant in our company.

Preliminary preparation

□Compatibility and adhesion test

The engineering contractor must provide all substrate samples that come into contact with structural sealant that are officially used in the project. Generally including glass, aluminum profiles, double-sided adhesive strips, etc. And entrust our company to conduct compatibility and adhesion tests in the form of submission.

Verification of engineering drawings and calculation of joint size for structural adhesive design

The contractor must review the design of silicone structural adhesive bonding nodes and calculate the size of structural adhesive joints in accordance with the engineering drawings and relevant design parameters, and JGJ102 "Technical Specification for Glass Curtain Wall Engineering". To achieve the most reasonable node design and adhesive joint design.

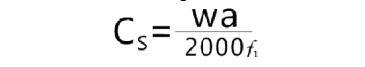

(1)Under wind load, the bonding width C should be calculated using the following formula:

In the formula, Cs - bonding width of silicone structural sealant (mm);

w- Design value of wind load acting on the calculation unit (kN/mm) ²

a-rectangular glass plate the short edge length(mm);

F1- The strength design value of silicone sealant under wind load or earthquake action, taken as 0.2N/mm ²。

Based on the specific situation, comprehensively consider the self weight effect of glass, seismic effect, temperature difference effect, etc., and design the bonding width of structural sealant.

calculation.

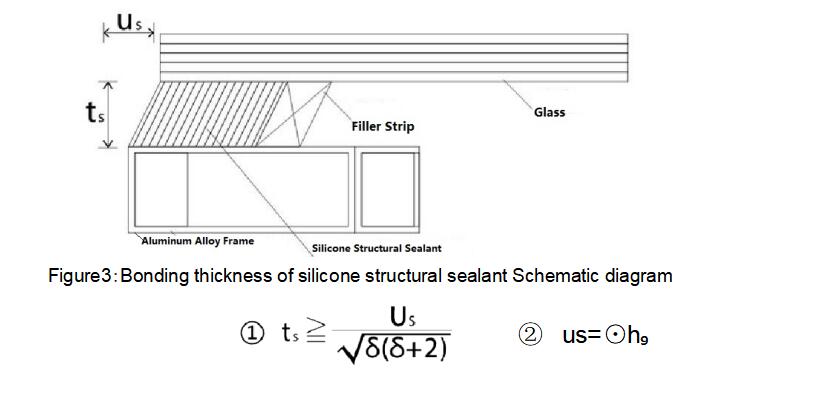

(2)The bonding thickness Ts (Figure 3) of silicone structural sealant should meet the requirements of formula ①

Formula ts-silicone structural sealant bonding thickness(mm)

us-curtain wall glass relative to aluminum alloy frame displacement (mm),The relative displacement generated by the lateral displacement of the main structure can be calculated according to equation ②

The displacement caused by temperature changes should be considered;

Q-Limit of elastic interlayer displacement angle of the main structure under the action of wind load standard value (rad)

HG - height of glass panel (mm), taking its side length a or b;

δ- The displacement bearing capacity of silicone structural sealant, corresponding to its tensile stress of 0.14N/mm² Elongation.

☑Construction Basic requirements

□Construction personnel Requirements

Realizing the bonding and sealing of single components of glass curtain walls relies on the high sense of responsibility and strict and proficient correct operation of construction operators, who should have the following conditions;

·High sense of responsibility and understand that the safety, reliability, and construction quality of glass curtain walls are closely related.

·Familiar with the construction process of structural sealant, proficient in bonding and sealing operation techniques and construction tools; Able to understand the bonding and sealing parts specified in engineering drawings and the condition of supporting materials.

·Master the basic knowledge of troubleshooting methods and technical safety after adhesive sealing failure.

□Construction technical conditions Requirements

·Special tools must be used during application。

·Keep the environment well lit, clean, and equipped with measures such as fire prevention, explosion prevention, and dust prevention.

· The construction environment temperature is generally not less than 10 ℃, and the relative temperature is not less than 40%. Verify the production date, certificate of conformity, inspection report, joint calculation report, compatibility and adhesion test report of structural sealant, and ensure that the product meets the standards and curtain wall design requirements.

◎ Process procedures

□ substrate surface cleaning

Adhered material surface cleaning plays a decisive role in the quality of the project, therefore, strict surface cleaning is the key to ensuring project quality.

. Cleaning agents are usually isopropanol, xylene, or butanone. The cleaning cloth should be a clean, fluffy white cloth.

. Clean the surface of the adhered material using the "double cloth wiping method":

. Soak a clean cloth with solvent and wipe the adhered surface, only in one direction.

.Before the solvent evaporates, immediately wipe off the solvent on the surface of the adhesive with a second dry and clean cloth,and do not allow the solvent to dry up on the surface. The cloth should be replaced regularly to ensure that it does not cause secondary pollution to the surface.

.The cleaning width should always be greater than the bonding and sealing construction width, usually around 1c m on both sides.

·When cleaning deep and narrow areas, a clean cloth can be wrapped around a suitable tool and wiped according to the above procedure.

·The cleaned substrate must be glued within 1 hour, otherwise it must be cleaned again

·Inspection of cleaning quality: Use a clean white cloth to wipe the adhered surface, ensuring that the cloth is free of contamination.

·The cleaned surface is not allowed to be contaminated again by hand contact or any other method. The surface that is not coated with glue within 1 hour after cleaning should be cleaned again before applying glue before construction.

☑Note

·Keep the operation site good ventilation conditions and safety protection measures such as fire and explosion

prevention, while comply with the technical safety regulations for the use of organic solvents.

.When using solvents,pour out of the container to soak wiping cloth. Not allowed to immerse the wiping cloth in the solvent to avoid contaminating the solvent, nor allowed to spray or apply solvent on the adhered surface, causing the solvent to overflow on the adhered surface, causing oil stains to dissolve and spread to a larger area.

☑Primer application

Do compatibility and adhesion testbefore determine.

Correct using primer helps to produce strong and continuous sealing adhesion on surfaces that are uneasily adhered to. How to use primer should strictly follow below methods:

·Use primer after cleaning the substrate and before injecting adhesive。

·Use a natural hard bristle brush or a clean, fluffy white cloth to apply a thin and uniform layer of primer to the adhered surface. Do not pour or overuse the primer. If necessary, cover the edges of the adhered surface to prevent primer from being applied to areas outside the adhered surface.

.After primer to the surface,please bond and seal with adhesive within 1 hour. Apply adhesive immediately after the primer dries, when much dust.

The primer contains volatile and flammable solvents, so apply under well ventilated conditions, and take safety measures such as fire and explosion prevention.

☑Structural sealant injection and finished products maintenance

·Before injecting sealant, cover sealant area outer edge horizontal surface with protective tape to prevent these areas contamination during scraping.

·Directly apply one-component silicone sealant using manual or pneumatic guns. When using pneumatic guns,Adjust operating pressure to prevent bubbles from forming during injection.

·Gun nozzle caliber should be less than the interface thickness, so that the gun nozzle extends into half of the depth of the interface. The gun nozzle should move evenly and moderately to ensure that the interface is filled with structural glue. When injecting glue, prevent from moving too fast or reciprocating, resulting in bubbles or cavities.

·After completing sealant injection, promptly compact the extra feet outside the interface inward with a scraper to make the structural sealant come into contact with the side edges of the interface, reduce internal bubbles and cavities, and ensure full contact between the structural sealant and the adhered surface. Finally, scrape the interface surface flat in the same direction.

·After finishing, remove the protective tape timely,and mark the date and No. on the unit plate glass or name frame,and place it horizontally for maintenance.

· Two component silicone structural sealant must be mixed evenly using a dedicated sealing equipment according to the specified proportion, and the mixture must be tested using the butterfly test method and recorded.

.Relocation time: Under standard conditions, one-component curing is 7 days, two-component curing is 12 hours.

.Complete time:Under standard conditions, one-component curing is 14 days, two-component curing is 7 days.

☑Quality Control

☑ Visual inspection

Inspect the apperance of already made curtain wall glass structure,conducting a block by block. The structural sealant should be filled with the adhered area without bubbles or cavities, otherwise cut at the bubbles or cavities, and replenish on the fresh adhesive surface with the structural sealant in a timely.

☑Sealant injection method

Install appropriate gasket materials, adhesive barriers, or tape.

Continuously squeeze silicone structural sealant into and fill the joint,use appropriate force to compact the sealant onto the gasket material and joint surface when sealant surface is not yet skinned.Recommend to use convex tools to trim the adhesive surface into a concave shape, don’t use soap or water as auxiliary materials for trimming.

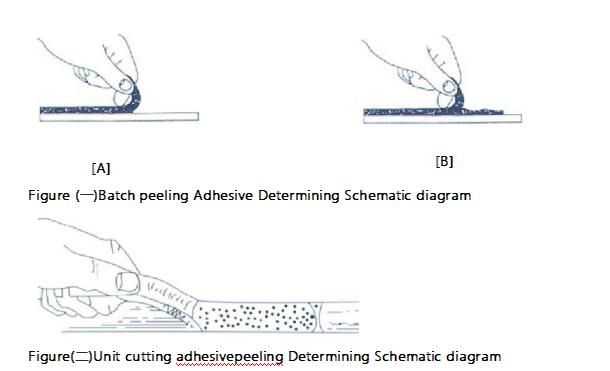

☑Finished unit components Adhesion Inspection

· Randomly select 3-5 pieces from every 100 unit (two-component structural sealant should be cured for at least 4 days, one-component structural sealant should be cured for 10 days), cut the structural sealant between the assembly frame and glass to separate the glass and aluminum frame, then cut the structural sealant with a knife, and cut a 50cm long adhesive strip horizontally along the substrate. As shown in Figure 2, grip the structural sealant strip tightly with your hand and peel it in a direction greater than 90 °, Check for cohesive damage or detachment of structural sealant, and record the percentage of cohesive damage.

·After the inspection, the inspection area should be repaired according to the sealant injection construction procedure. The original structural sealant surface should be clean and fresh, and have good adhesion with the original structural sealant.

·Delivery inspection

For single components of curtain wall glass structure produced, delivery inspection should be carried out batch by batch. Acceptance can only be carried out when the bonding reaches cohesive failure and there are no bubbles or cavities in the appearance inspection.

Fill in the construction quality inspection report once pass the inspection and the inspector should fill in the inspection record and sign it before the product shipment.

☑Technical Support Services

□Quality Assurance

Our company provides quality assurance for design strictly in accordance with relevant standards and constructed in accordance with our company's product construction specifications.

☑on-site technical support

Our technical personnel can assist customers using our products correctly before or during construction. Including substrates cleaning, correct use of sealants, etc. Customers can contact our technical department or local sales company in advance to obtain timely technical support from us.

Current location:

Current location:

hot product

hot product

hot news

hot news

message

message detail

detail