【Product Name】

OM618 Silicone Hollow Sealant

【Product description】

Two-component silicone sealant OM618 is neutral,High modulus silicone elastomer sealant, which can quickly cross-link at room temperature to form a permanent elastomer.Good adhesion to most substrates, including coated glass, glazed glass, anodic aluminam and stainless steel.It is non-polluting and non-corrosive to the bonded substrate and has good stability in the working environment of -60°C~180°C.

【Product advantages】

⊙Good air tightness

⊙Excellent aging resistance

【Application area】

OM618 is used for edge sealing and sealing of insulating glass in building, transportation,refrigeration and other industries.

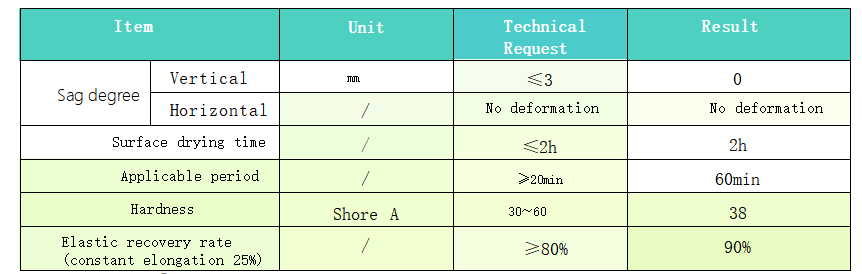

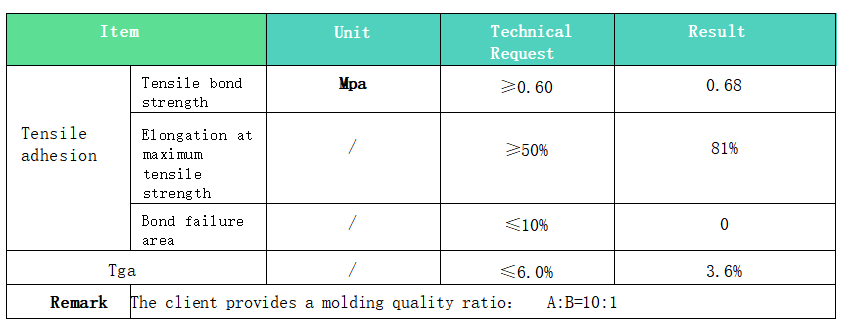

【Main technical indicators】

【Product description】

OM618 is a two-component silicone hollow glass sealant, mainly used for sealing and bonding of glass, metal and other components.Neutral dealcoholized,solidified at room temperature and released a small amount of alcohol gas.

【Related standards】

OM618 can meet the Chinese standards GB/T29755,JG/ T471,with low water vapor permeability, good adhesion,thus ensuring a longer service life of the sealant.

【Usage method】

OM618 has good adhesion to most coated and non-coated glasses, metal spacerstrips and so on without primer.In order to ensure the quality of the project, it is recommended that compatibility and caking tests ahead of timebefore each project starts.

【Mixing ratio】

In order to obtain better physical properties, it is recommended that the base glue and curing agent be mixed in a fully closed stirring system. Automatic glue beater can be used instead of hand or hand-held agitator.Airis easily brought in during the mixing process, which affects the physical properties of the sealant after curing.In orderto obtain the best sealant performance, the ratio of base rubber to curing agent should be mixed according to the mass ratio of 12:1 or the equivalent volume ratio of 8.0:1.Under the mixing ratio, the construction period of the sealant should be 30min~50min, and the drying time is within 2H.The mixing ratio is allowed to be adjusted in a small range, but the mass ratio is best between the range of 11:114:1.It is recommended that the curing agent be evenly stirred before use. Because the curing agent is easy to react with the moisture in the air, it can not be exposed to the airforalong time.

【Preparatory work】

Remove dirt from substrate surface, such as grease,oil, dust, water, frost, old sealant, glass compound,protective coating,etc. Metal, glass and plastic surfaces should be cleaned by mechanical means orsolvents.Choose clean,velvet-free white cloth dipped in a solvent to wipe the surface of the substrate, and then wipeit with anotherdry, clean, velvet-free white cloth.

【Primer】

OM618 generally does not require primers.Compatibility tests before use will be done to determine whether primers are used through compatibility orcaking test results.

【Protection and construction】

In order to ensure the appearance and cleanliness, we should use protective tape to cover the adjacent seams during construction.It is not allowed to contact the adhesive tape, that is, the area where silicone sealant will adhere. The adhesive tape should be removed immediately afterfinishing the finishing process.

【Equipment cleaning】

After finishing the glue, it is necessary to use the base glue to rinse the pipe of the glue mill or to wash it with solvent.If the cured sealant already exists inside the equipment, the appropriate solvent should be selected to clean immediately to ensure the surface of pipe is clean after cleaning.

【Repair】

If there is damage of sealant, the damaged sealant should be removed with a clean knife,then inject new sealant.

【Matters needing attention】

Before construction, please read the product instructions, safety data sheets, packaging labels carefully to obtain information on safeuse and health hazards.

【Shelf life and storage】

The well-packaged product can be stored in a cool, ventilated and dry place for 12 months below 30℃ and used before the expiration of the product package.

【Packing】

The net capacity of A component is 190L

The net capacity of B componentis 19L

The net capacity of A componentis 19L

The net capacity of B componentis 1.9L

【Usage restrictions】

This product is not suitable for:

◆On the surface of building materials that may seep oil, plasticizers, solvents, or partially vulcanized rubber gaskets or tapes

◆Areas that have suffered excessive friction or physical damage

◆A completely sealed place during curing

◆A frosted or damp surface

◆Applications that come into direct contact with food or other food-grade surfaces

【Transportation】

This product is non-hazardous and can be transported by train, car, ship and plane.

【Safety Instructions】

This product manual does not include all the information on safety usage instructions. To ensure safe construction, carefully read the construction guide and product manual before use, and contact the local sales company to obtain these materials. Especially for the bonding of chrome-plated surfaces (such as chrome-coated glass), it is necessary to contact the technical department of our company before use and conduct a safety test before use.

Current location:

Current location:

hot product

hot product

hot news

hot news

message

message detail

detail